06, 2019

by oreelaser

As we all know that the vulnerable parts of fiber laser cutting machine are just a few: ceramic ring, nozzle, reflector and laser head protective mirror. Let’s go to the topic directly, explain how these vulnerable parts should be replaced and the consideration for selection.

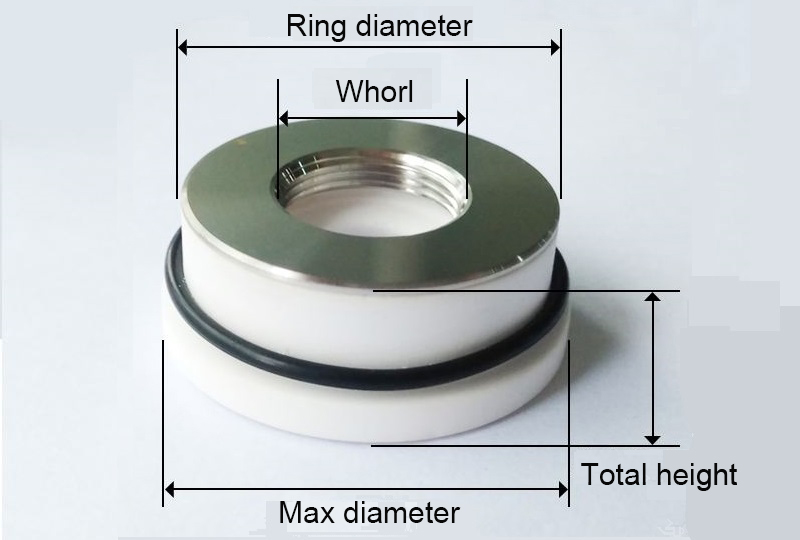

First of all, let us start with the ceramic ring. The ceramic ring is mounted on the laser cutting head above the nozzle, under the sensor (see picture), which is responsible for transmitting and collecting the cutting signal emitted by the nozzle, in order to prevent the nozzle from colliding with the plate during operation, which will damage the cutting head. The ceramic ring is more resistant to high temperature and deformation.

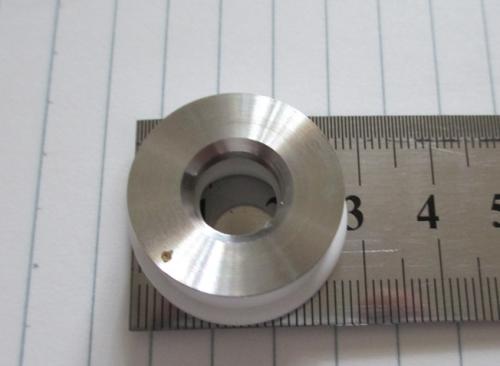

The common structure of ceramic ring is shown in the figure. The main structure includes: ceramic body, stainless steel sheet and copper column.

1. Ceramic body. Among them, there are two kinds of raw materials commonly used in ceramic bodies, namely ZrO and AlO. And the ZrO is more expensive than the AlO in Chinese market. The advantage of using ZrO as a ceramic ring is that it has a very small coefficient of thermal expansion (high temperature resistance), high density (resistance to wear and tear), and high electrical resistivitiy. This kind of ceramic body can effectively ensure the insulation of important parts and the cutting head, and further reduce the loss of the cutting head. Of course, it is reasonable to use AlO to reduce costs, but the replacement period of vulnerable parts is shortened.

2. Stainless steel sheet. Everyone knows that metal is generally used to transmit signals. The bump contact between the stainless steel sheet and the nozzle can accurately and rapidly transmit the electrical signal to the copper needle.

If you want to reduce the deformation of the thin stainless steel plate at high temperature, it will also require many steps to deal with.

3. The copper column acts as a medium to relay the electrical signals that collected by the stainless steel sheets to the internal transmission line of the laser head, which ensure that the controller can be randomly adapted. The propagation of electrical signals requires high electrical conductivity, so gold plating is an effective method.

In addition, you need to pay attention to the adhesive--conductive silver glue, which can effectively and firmly adhere to those three parts, high temperature will not fall apart, ensure the overall conductivity, and ensure the safe operation of the laser head. Good ceramics will hardly affect the original laser path after replacement, no need to re-adjust, saving time and effort.

Ceramic ring replacement method:

Firstly, unscrew the nozzle; Secondly, unscrew the lock of the ceramic ring. During the process of rotation, the fingers should hold the old ceramic ring to prevent it from falling down vertically. Thirdly, when replacing a new ceramic ring, it is necessary to align the copper column with the induction hole at the bottom of the cutting head. Normally, the aligned ceramic ring will be horizontal and will be a little elastic, and the left and right cannot be rotated. Finally, at the same time, after the installation, the beam path should be adjusted to prevent the deviation of light.

Professional Laser Cutting Machine Manufacturer - OreeLaser